When it comes to working with metal, terms like metal fabrication and welding are often used interchangeably. However, these two processes serve distinct roles in manufacturing and construction. If you’ve ever wondered, “Is metal fabrication the same as welding?” this article breaks down their differences, applications, and how they complement each other.

What is Metal Fabrication?

Metal fabrication is a broad term that encompasses multiple processes used to shape, cut, bend, and assemble metal into finished products. It involves transforming raw metal materials (e.g., sheets, rods, or bars) into structures or components through techniques such as:

-

Cutting: Using tools like lasers, plasma torches, or shears.

-

Bending: Employing press brakes or rollers.

-

Machining: Removing material via drilling, milling, or grinding.

-

Assembly: Joining parts with fasteners, adhesives, or welding.

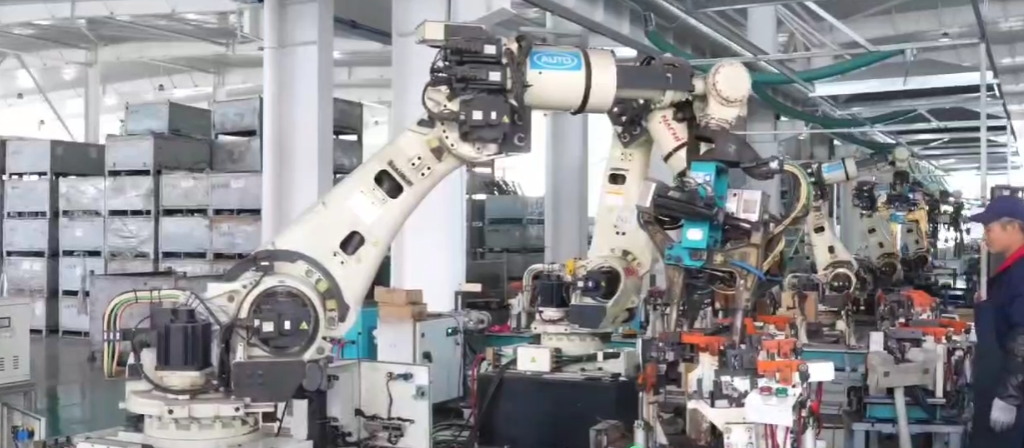

Metal fabrication is used to create everything from automotive frames and HVAC systems to architectural structures and custom machinery.

What is Welding?

Welding is one specific technique within metal fabrication. It focuses on joining two or more metal pieces by melting their edges and fusing them together, often with a filler material. Common welding methods include:

-

MIG Welding: Uses a wire electrode and shielding gas.

-

TIG Welding: Precision welding with a tungsten electrode.

-

Stick Welding: Portable and ideal for heavy-duty repairs.

-

Spot Welding: Joins overlapping sheets at specific points.

Welding is critical for creating strong, permanent bonds but is just one step in the larger fabrication process.

Key Differences Between Metal Fabrication and Welding

-

Scope

-

Metal Fabrication: A comprehensive process involving design, cutting, shaping, and assembly.

-

Welding: A specialized task focused solely on joining metals.

-

-

Skills Required

-

Fabricators need expertise in reading blueprints, operating machinery, and multiple techniques.

-

Welders require mastery of heat control, joint preparation, and safety protocols.

-

-

Applications

-

Fabrication produces entire products (e.g., staircases, enclosures).

-

Welding ensures structural integrity in joints (e.g., pipelines, vehicle frames).

-

-

Tools and Equipment

-

Fabricators use shears, CNC machines, and press brakes.

-

Welders rely on welding torches, electrodes, and protective gear.

-

How Welding Fits Into Metal Fabrication

While welding is a subset of fabrication, the two processes often collaborate. For example:

-

A fabricator cuts and bends sheet metal to form parts of a gate.

-

A welder joins these parts to create the final structure.

-

The fabricator finishes the product with polishing or painting.

Welding ensures durability, while fabrication handles the overall design and functionality.

Common Misconceptions

-

“All fabricators are welders.”

Not true—fabricators may subcontract welding or specialize in non-welding tasks. -

“Welding is the only way to join metal.”

Alternatives like riveting, bolting, or adhesives are also used in fabrication.