Laser Cutting Technology: In-Depth Applications Revolutionizing Sheet Metal Fabrication

The manufacturing landscape has been transformed by laser cutting technology, a cornerstone of modern sheet metal fabrication. As industries demand higher precision, faster turnaround, and greater design flexibility, laser cutting has emerged as an indispensable metal processing solution. This article explores the profound applications of this technology and highlights how Beijing JCEN Company—with three decades of sheet metal experience—masters these advanced techniques to serve global clients.

The Evolution of Laser Cutting in Metal Fabrication

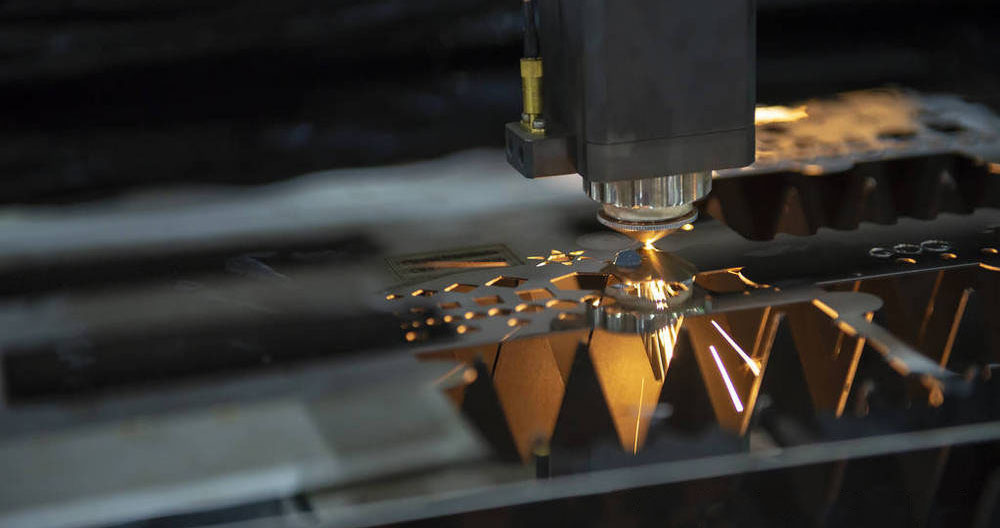

Laser cutting utilizes a high-powered, focused beam to melt, burn, or vaporize materials with exceptional accuracy. Initially adopted for specialized tasks, it now underpins mass production across sectors like aerospace, automotive, electronics, and construction. The process excels in cutting, engraving, and perforating metals—from stainless steel and aluminum to copper and brass.

Key advantages include:

-

Precision Cutting: Tolerances within ±0.1 mm enable complex geometries.

-

Versatility: Handles various metal thicknesses and types.

-

Speed and Efficiency: Rapid prototyping and high-volume production.

-

Minimal Material Waste: Optimized nesting reduces scrap.

-

Superior Edge Quality: Often eliminates secondary finishing.

Core Applications in Sheet Metal Fabrication

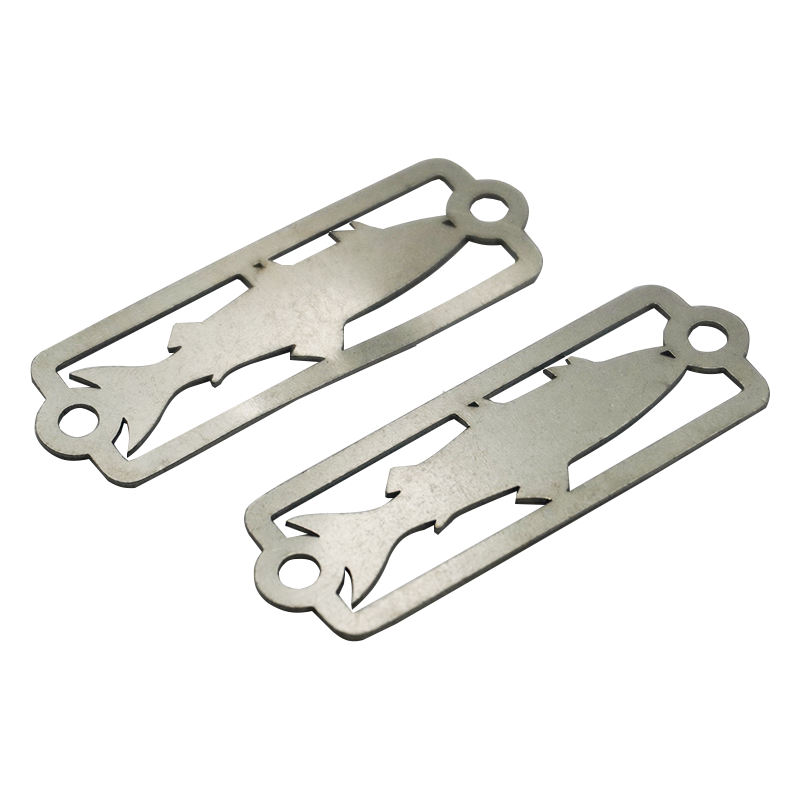

1. Precision Component Manufacturing

Laser cutting produces intricate parts for machinery, enclosures, and assemblies. Beijing JCEN Company applies its 30 years of expertise to fabricate components with exacting specifications, ensuring seamless integration in end-products. Processes like bending, forming, and welding complement cutting for complete solutions.

2. Custom Architectural and Design Elements

From decorative panels to structural supports, laser technology enables creative and functional designs. Etching, marking, and cutting facilitate unique textures and patterns, meeting aesthetic and technical demands.

3. Rapid Prototyping and Low-Volume Production

The technology accelerates development cycles. JCEN’s proficiency in CAD/CAM programming and laser operation allows quick transitions from design to tangible parts, ideal for prototyping and custom orders.

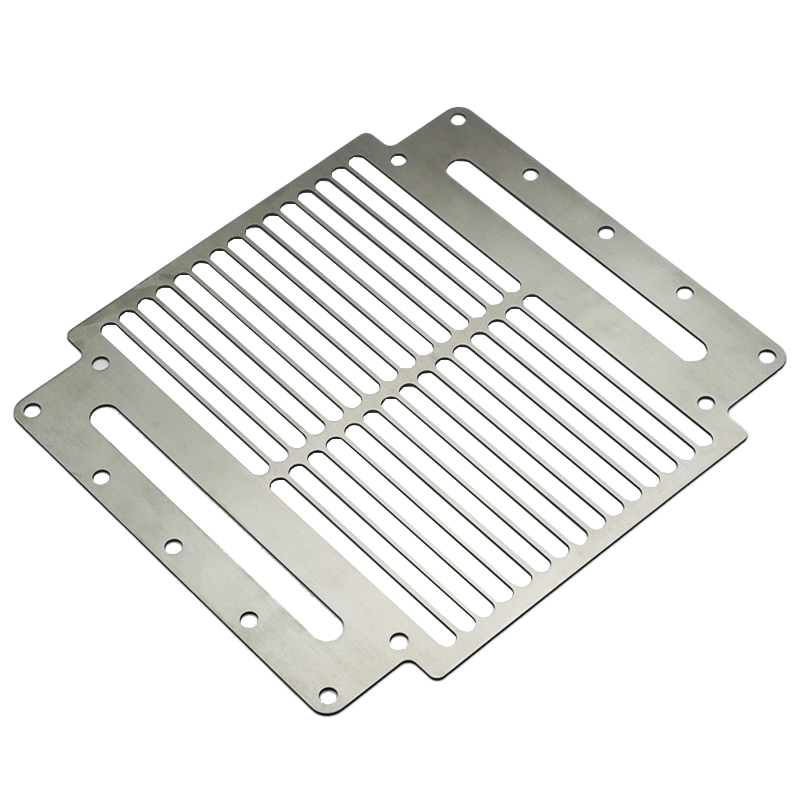

4. High-Volume Industrial Parts

Automated laser systems ensure consistency in large batches. Integrated with CNC punching, stamping, and pressing, they form a complete fabrication workflow. JCEN’s long-term experience ensures reliability even in demanding production schedules.

Integrating Laser Cutting with Traditional and Modern Processes

A holistic manufacturing approach combines laser cutting with other techniques:

-

Bending and Forming: Post-cutting, press brakes shape parts accurately.

-

Welding and Assembly: TIG, MIG, and spot welding join laser-cut pieces.

-

Surface Treatment: Powder coating, anodizing, and plating enhance durability and appearance.

-

Quality Control: Inspection and testing guarantee adherence to blueprints and tolerances.

Beijing JCEN Company exemplifies this integration. Its three-decade journey in sheet metal fabrication encompasses laser cutting, CNC machining, stamping, and fabrication finishing. This comprehensive capability ensures end-to-end service—from material selection (including galvanized steel, aluminum sheets, and stainless steel) to final assembly and packaging.

Technological Advancements and Industry 4.0

Modern laser cutters feature fiber laser sources, offering higher efficiency and lower maintenance than CO₂ lasers. Automation via robotic loading/unloading and IoT connectivity enables lights-out production. Software for nesting and simulation optimizes material usage and prevents errors.

JCEN stays at the forefront by investing in advanced laser systems and CNC equipment. Their team’s skills in programming, tooling, and process engineering translate into superior manufacturability and cost-effectiveness for clients.

Why Choose an Experienced Partner?

Sheet metal fabrication involves numerous variables: material properties, tolerance requirements, production volume, and finish standards. Inexperience can lead to costly errors in cutting, bending, or welding.

Beijing JCEN Company brings 30 years of sheet metal experience to every project. Their expertise covers:

-

Design for Manufacturability (DFM) guidance

-

Material sourcing and quality assurance

-

Precision fabrication across processes

-

On-time delivery and competitive pricing

This seasoned approach minimizes risks and ensures that each component—whether a simple bracket or a complex chassis—meets the highest standards of precision engineering.

Conclusion

Laser cutting technology is more than a cutting tool; it is a transformative force in sheet metal fabrication. Its applications span from delicate etching to heavy-duty plate cutting, driving innovation across industries.

For businesses seeking a reliable fabrication partner, Beijing JCEN Company stands out with its deep technical knowledge, honed over 30 years in sheet metal processing. By leveraging state-of-the-art laser cutting alongside complementary services like stamping, welding, and finishing, they deliver comprehensive solutions that blend quality, efficiency, and innovation.

Embrace the future of metal fabrication with a partner whose experience ensures your success. Contact Beijing JCEN Company to discuss your next project.