What Are the Three Basic Types of Sheet Metal Fabrication?

Sheet metal fabrication is a cornerstone of modern manufacturing, essential for creating everything from industrial enclosures and automotive components to aerospace parts and electronic chassis. At its core, this process transforms flat metal sheets into specific shapes and structures. For businesses and engineers seeking reliable fabrication services, understanding the three basic types—cutting, bending, and assembling—is crucial.

With over 30 years of dedicated experience, Beijing JCEN has mastered these foundational processes. Our deep expertise ensures that every project, from prototype to full production run, meets the highest standards of precision, durability, and efficiency.

1. Cutting: The First Step in Shaping Metal

Cutting is the initial stage where large sheets of metal are divided into smaller, workable pieces. Modern sheet metal fabrication utilizes advanced techniques that go far beyond simple shearing.

-

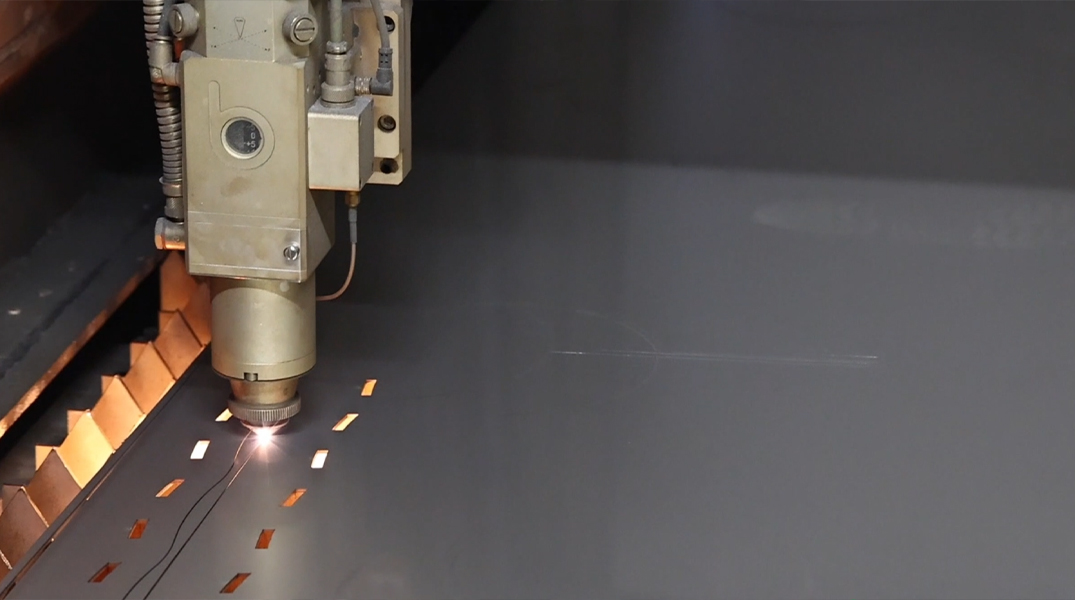

Laser Cutting: A highly precise and versatile method, ideal for complex designs and tight tolerances. It’s a key service in our precision sheet metal fabrication offerings.

-

Plasma Cutting: Best for thicker materials, offering speed and power for robust industrial parts.

-

Waterjet Cutting: Uses a high-pressure stream of water and abrasive, perfect for materials sensitive to high heat from other processes.

-

Punching and Stamping: Creates holes or specific shapes using dies and presses, fundamental for high-volume metal stamping.

Beijing JCEN leverages state-of-the-art CNC machining and cutting technology to ensure flawless accuracy, minimal material waste, and clean edges ready for the next fabrication stage. Our metal fabrication services begin with cutting strategies optimized for cost-effectiveness and quality.

2. Bending: Forming the Angle and Structure

Once cut, the metal sheets are formed into three-dimensional shapes through bending. This process requires expert knowledge to account for metal forming properties and springback.

-

Press Brake Forming: The most common method, using a press brake and precision-designed dies to create consistent, accurate bends. Our sheet metal design expertise ensures bend allowances are perfectly calculated.

-

Roll Bending: Used for creating curved or cylindrical parts like tubes and housings.

-

Folding: A specialized technique for specific fabrication needs.

With three decades of experience, Beijing JCEN technicians expertly handle a vast range of materials and thicknesses. Our prototyping and custom sheet metal fabrication processes rely on this deep metalworking knowledge to produce durable, dimensionally perfect parts every time.

3. Assembling: Bringing Components Together

The final basic type involves joining the fabricated pieces into a finished product. The right assembly technique is vital for structural integrity and appearance.

-

Welding: A permanent joining method, with techniques like MIG, TIG, and spot welding chosen based on the material and application. This is a core part of our welding and fabrication capabilities.

-

Riveting: A mechanical fastening process ideal for parts that may require disassembly.

-

Adhesive Bonding: Uses industrial-strength adhesives for certain materials and designs.

-

Fastening with Screws/Bolts: Allows for non-permanent assembly and easy maintenance.

Beijing JCEN’s assembly department ensures strong, clean, and reliable joints. Whether for electrical enclosures, machine components, or custom enclosures, our final product assembly meets rigorous quality control standards.

Why Beijing JCEN’s 30 Years of Experience Makes the Difference

Mastering cutting, bending, and assembling is just the start. True excellence in sheet metal fabrication comes from decades of applied knowledge, investment in technology, and a commitment to quality.

-

End-to-End Solutions: We are a full-service metal fabricator offering laser cutting, CNC punching, bending, welding, powder coating, and finishing services.

-

Material Expertise: We work with aluminum, stainless steel, cold rolled steel, galvanized steel, and more, providing expert material selection advice.

-

Industry-Specific Knowledge: Our solutions serve aerospace, automotive, telecommunications, industrial equipment, and construction sectors.

-

Quality & Precision: From CAD design and engineering support to precision machining and final inspection, our quality control is unmatched.

-

Efficiency & Scalability: We support both low-volume prototype fabrication and high-volume production runs, ensuring cost-effective fabrication and reliable lead times.

Partner with a Trusted Expert

For three decades, Beijing JCEN has been a leader in transforming raw metal into critical components and assemblies. Our deep-rooted expertise in the three basic types of sheet metal fabrication, combined with advanced technology and a client-focused approach, ensures your project’s success from concept to completion.

Contact Beijing JCEN today to discuss your project requirements and experience the difference that 30 years of dedication to excellence can make.