_01.jpg)

_09.jpg)

_06.jpg)

_04.jpg)

_03.jpg)

Metal Surface Treatment: Enhancing Durability and Aesthetics in Sheet Metal Fabrication

Metal surface treatment is a critical stage in the sheet metal fabrication process, transforming raw components into durable, functional, and visually appealing final products. These processes are vital for improving corrosion resistance, wear properties, and preparing surfaces for further operations like welding or painting. For industries ranging from automotive and aerospace to electronics and construction, the right finish is paramount.

As a leader with 30 years of experience in sheet metal fabrication, Beijing Jiacheng understands that superior surface treatment is the cornerstone of product longevity and performance. Our expertise ensures every project benefits from precise and reliable finishing techniques.

Why is Metal Surface Treatment Essential?

Post-fabrication, metal surfaces are often vulnerable. Treatment provides a protective barrier against environmental factors, prevents oxidation, reduces electrical resistance, and can enhance adhesion for coatings. Key benefits include:

-

Corrosion Protection: Shields against rust and degradation.

-

Improved Wear Resistance: Increases surface hardness and lifespan.

-

Enhanced Aesthetics: Provides a uniform, clean, or decorative finish.

-

Better Paint Adhesion: Creates an optimal surface for subsequent coatings.

-

Modified Electrical Properties: Can improve conductivity or insulation.

Common Metal Surface Treatment Techniques

The chosen method depends on the base material—such as stainless steel, aluminum, or carbon steel—and the desired outcome. Here are some fundamental processes:

1. Cleaning & Pre-Treatment (Degreasing & Descaling)

Before any finishing, surfaces must be immaculate. This involves degreasing to remove oils and descaling to eliminate mill scale or oxides. Techniques include alkaline cleaning, solvent cleaning, and abrasive blasting. This foundational step is crucial for welding, powder coating, and other metal finishing steps.

2. Conversion Coatings

These chemical treatments create a layer that improves paint adhesion and corrosion resistance.

-

Phosphating: Common for steel before painting or oil coating, providing a crystalline phosphate layer.

-

Chromating: Often used on aluminum and zinc for corrosion protection and paint bonding.

-

Anodizing: An electrochemical process primarily for aluminum, increasing oxide layer thickness for durability and allowing for color dyeing.

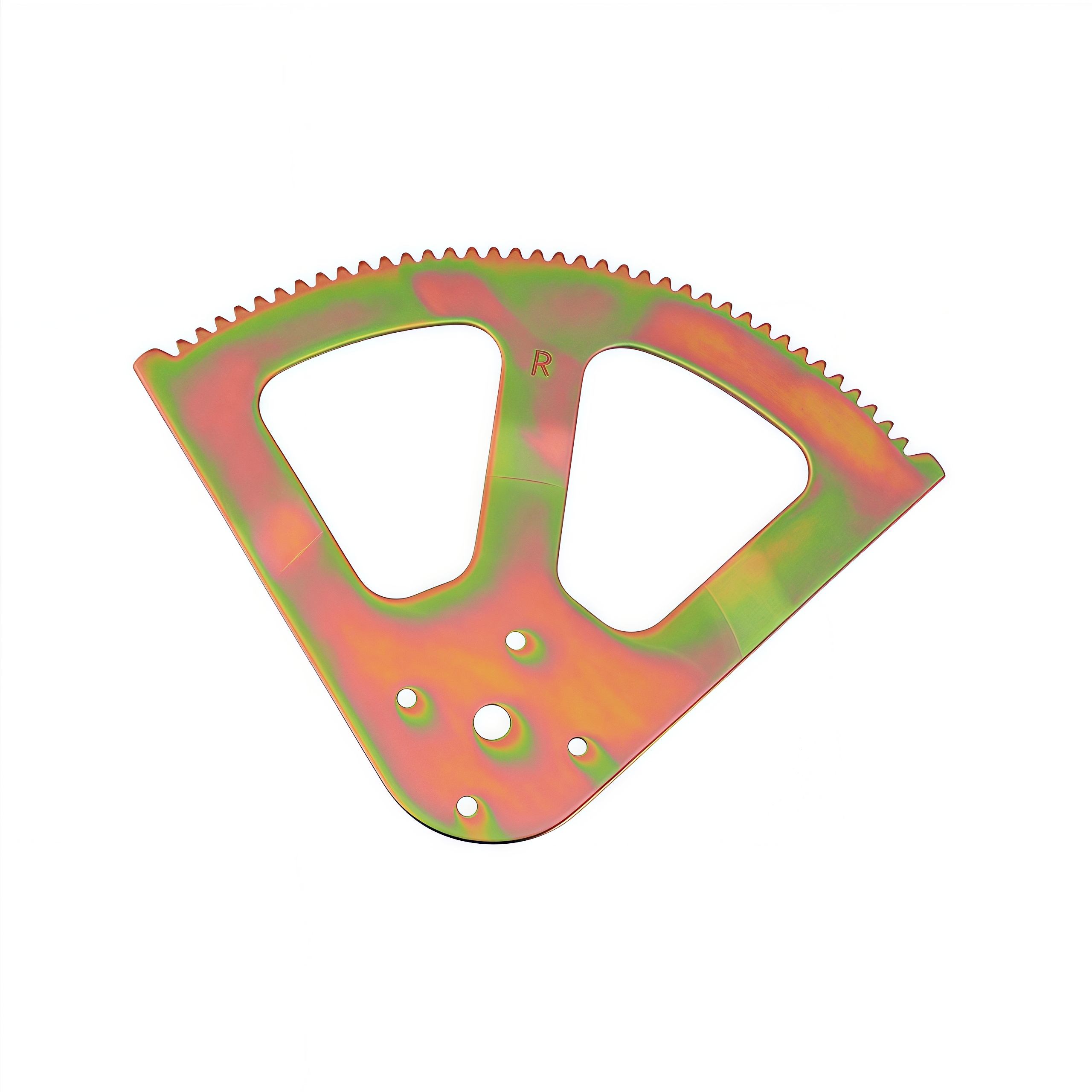

3. Plating & Electroplating

This involves depositing a thin metal layer (like zinc, nickel, or chrome) onto the substrate via electroplating. Zinc plating (galvanization) is widely used for sacrificial corrosion protection on steel fasteners and components. It’s a core aspect of metal manufacturing for both function and appearance.

4. Paint & Organic Coatings

These provide color, texture, and an additional protective barrier.

-

Powder Coating: A dry finishing process where electrostatically charged powder is applied and cured under heat. It’s durable, eco-friendly, and offers excellent coverage for sheet metal enclosures and cabinets.

-

Liquid Painting: Includes spray painting for versatile applications and finishes.

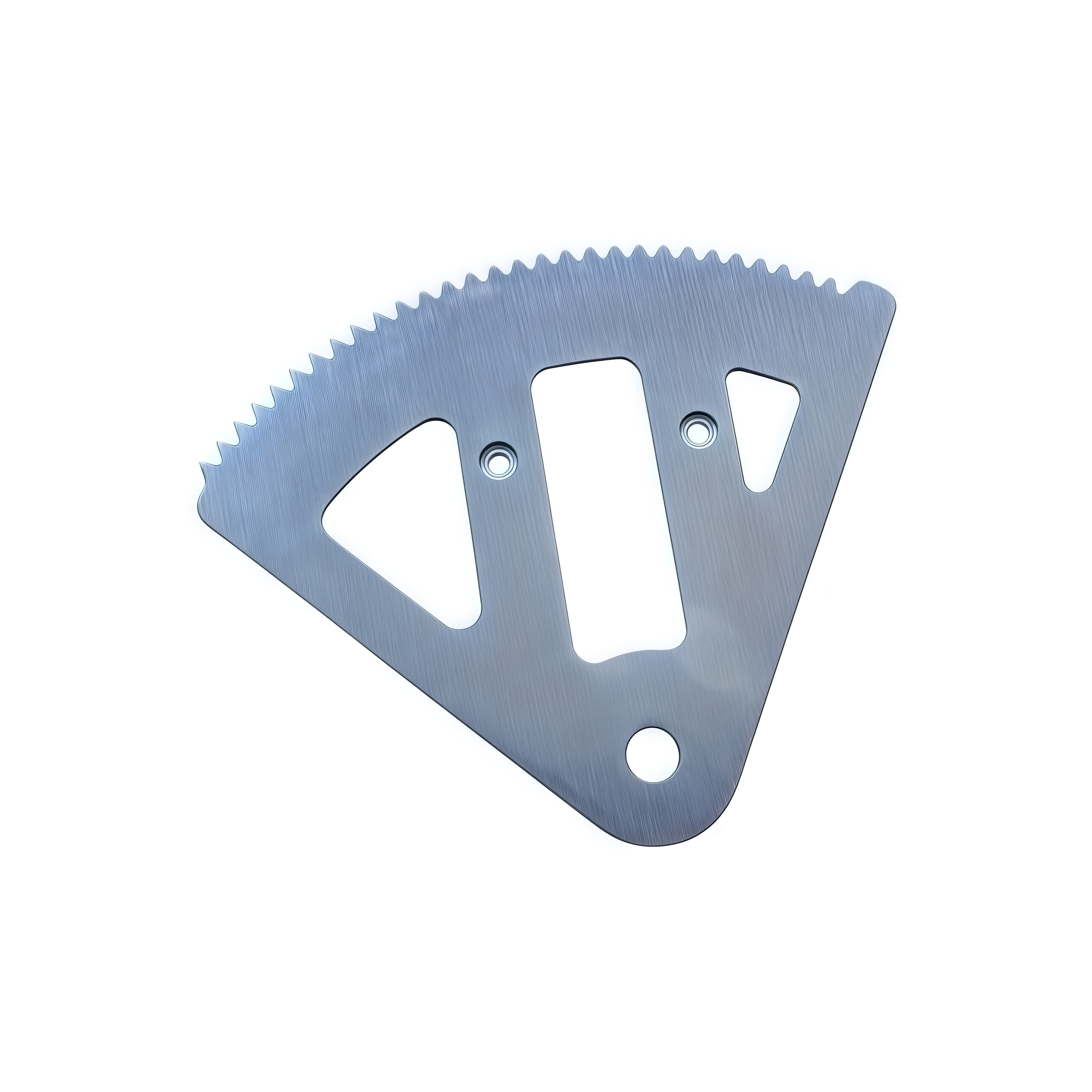

5. Mechanical Finishes

These alter the surface texture or appearance through physical means.

-

Polishing & Buffing: Achieves a smooth, reflective surface on stainless steel.

-

Abrasive Blasting: Uses media like sand or glass beads to clean, smooth, or roughen a surface.

-

Brushing: Creates a uniform directional satin texture.

6. Advanced & Specialized Treatments

-

Passivation: A chemical process for stainless steel to remove free iron and enhance the natural chromium oxide layer.

-

Laser Cutting & CNC Machining Surfaces: Often receive specific edge treatments or deburring post-processing.

-

Heat Treatment: While often a bulk process, it can affect surface properties like hardness.

The Role of Fabrication Processes in Surface Preparation

The quality of the initial sheet metal fabrication dictates the success of the surface treatment. Precise cutting (via laser cutting or punching), bending, welding, and assembly create a part ready for finishing. Poor welding can lead to porosity, while inaccurate bending can cause stress points. With three decades of expertise, Beijing Jiacheng’s integrated approach from design and prototyping through fabrication and finishing guarantees impeccable preparation. Our services include comprehensive sheet metal services, stamping, and forming to ensure your part is perfect before the treatment even begins.

Beijing Jiacheng: Your Partner with 30 Years of Expertise

In the complex world of metal fabrication, experience translates to precision and reliability. For 30 years, Beijing Jiacheng has been a trusted provider of end-to-end sheet metal manufacturing solutions. Our deep knowledge of materials—from stainless steel and aluminum to galvanized steel—informs every choice we make in metal surface treatment.

We don’t just apply a finish; we engineer it. Our team considers the part’s function, environment, and aesthetic requirements to recommend the optimal process, whether it’s powder coating for an outdoor chassis, anodizing for a delicate electronic enclosure, or passivation for medical equipment. Our capabilities support the full production cycle, from custom fabrication and prototype development to high-volume manufacturing and assembly.

From CNC machining and sheet metal cutting to final quality control, our 30-year legacy is built on delivering durable, high-quality components that meet the strictest tolerances and standards. We serve diverse needs, including HVAC, electrical cabinets, machine frames, and precision parts.

Ready to elevate your next sheet metal project with expert metal surface treatment? Contact Beijing Jiacheng today to leverage our 30 years of sheet metal fabrication experience for a solution that guarantees durability, quality, and precision from the ground up. Request a quote or consult with our engineers on your custom metal fabrication needs.